By Jose S. Villegas

When people talk about kaizen, the word quality comes to mind. In Kaizen we don’t limit the concern of improvement to quality but to everything that will improve the business system. As our company name “Kaizen Management System” implies our concern is the improvement of the total business system which includes the improvement of the Kaizen System itself.

What does improving the Kaizen or Improvement System mean? This article discusses all the major aspects of improvements. It provides opinions about like: What is the ultimate objective of improvement? How do we know that our improvements will be beneficial to the customer? What is value-focused improvement? Does it help to tell the customers that we are improving for them? How about improving our goals as well? Is there a limit to improvement?

Strengthening the financial position of the company

The goal of a business enterprise is to make money. And the means to achieve goal is by making profit in the sales of its products or services. So the real activities (or transactions) of the company are everything that helps increase profit. We might call these activities as business activities. Non-business activities, hence, are those activities that don’t increase profit. Basically, there are three ways of looking at increasing profit and they are: increase the rate of exchange (sales), reduce cost, and increase price. Thus marketing, sales and new product introduction might be called active business activities because these are efforts to deliberately create profits (or surplus). On the other hand: cost reduction, process improvement, quality management might be called passive business activities because these don’t directly win profits by passing on a product or rendering a service to the customer.

In order to avoid unnecessary costs, the company must refrain from doing non-business activities. (But we know there are lots of them going around.) Our corporate culture oriented to make people busy can be driving up unnecessary costs. Managers want to see their people busy and people don’t want themselves to be seen idle. So people show what the management wanted to see – – “busy people”. This cat and mouse game between managers and workers doesn’t seem to increase profit at all instead this will most likely decrease it.

Who is to blame for these? Management will be quick on blaming people. And if this is so, no improvement happens. Everyone knows that a company makes money from results, not on people being busy. This being the reality, then a system of responsibility for results must guide every manager and worker. As long as results are there, why do we have to worry if people are busy or not? And if people aren’t busy enough then it is management’s fault having too many people. Too many people was a result of a non-kaizen management habit of hiring instead of thinking how to make do with the present level of human resource. This means that the management was not practicing Kaizen.

One of the most memorable speeches I ever heard was that one delivered by a Japanese glass lenses-making company during our Philippine 5-S Study Mission to Japan in 1993. It went like this: “Our company makes glass lenses. We make telescope, microscope, eye glass, concave, convex, big, small glass lenses. We try to focus all our efforts on our business and avoid activities that don’t make glass lenses. An example of the activities that we try to avoid is materials handling. Conveying and transportation don’t make glass lenses. So we try to eliminate this kind of activities. Instead, we focus our efforts on improving those activities that make glass lenses…”

The first step in Kaizen is to challenge why a process has to be done in the first place. Every process and step must be challenged because it is a cost. A Kaizen company will not knowingly do a non-value adding activity and reduce its profit-making potential or pass on the cost to its customers. Some activities camouflage like they are value adding but they really are not like “inspection”. Inspection doesn’t create value for the customer and, as you know, any activity is a cost that reduces profit. Inspection is classified as “muda” or process waste called overprocessing i.e. a process that is not needed. Our kaizen seminar on “Muda Elimination” describes all forms of “muda” and how they can be eliminated.

Process improvement and muda elimination, however, does not guarantee total system cost improvement. According to Eliyahu Goldratt, only those improvements directed at the system constraint will positively affect the bottomline. This puts to question the usual practice of widespread (often disorganized) company-wide improvement all because this may not be the cheapest and the most effective way of improvement. As you know, even improvements have costs and we must choose the alternative that is most effective and least costly. Improvement must also be managed so that efforts of people are not canceling each others effects.

Increased profit oftentimes means reduced cost but interestingly increase in price will also accomplish the same end. Nowadays where everything is increasing in price, a price increase may not be too bad.

Improvement that is Beneficial to the Customer

It seems that this idea is going head to head against the previous. How can improvement be strengthening your financial position while benefiting the customer at the same time? In Kaizen, we have demonstrated and proven in real life situations that these two ends are not at all opposite. What is beneficial to the customer may also be profitable to the company. The truth is: customers are more pre-occupied on their benefit than on the profit that you are making. As long as we give them what they want and they are satisfied they don’t care about the money we are making. But some customers do. I mean, some customers make sure that their suppliers are making enough or they are not losing because it is to their best interest that they continue to co-exist and share success with them.

As suppliers of products and services, our mission is to assure success of our customers. We should improve our understanding of our customers’ needs with respect to our outputs. Many of these have nothing to do with product design (which have already been agreed) but on delivery and customer support. Oftentimes we take actions only after being told to. Instead of reacting when its too late (i.e. when a competitor would have already figured it out or we are about to lose a customer), we have to adopt a proactive approach. We can only do that by improving our understanding of the customer through proactive communication. Being proactive means that we have to initiate the process of knowing how to support our customers better. Customers can sometimes be too busy to communicate requirements, more so, changes in requirements e.g. changes in forecast. So our job as suppliers is to touch base with our customers as often as we can, or even better, extend our information gathering to include our customers’ customers market information as well. Really excellent companies will analyze the whole supply chain and feed forward the information to their customers.

Improvement ideas that will easily be felt by the customer include just-in-time delivery, zero customer complaints, product or service reliability, prompt service response, order lead time reduction, and the like. Outside of these are improvement themes that are not really customer directed but those that we do for ourselves. Of course if we make our workplace more work-friendly our productivity might increase and that will also benefit the customer indirectly.

Value-focused Improvements

A customer will buy something that is of value. From the customer’s point of view, a thing is of value because it serves him/her a function or he/she believes that having it makes life better. Kaizen believes that all improvements must be customer driven, i.e., on the direction that the customer says. Value Analysis/Value Engineering (VA/VE) defines value on the basis of function. For example a product may be called telephone, but the function that it is serving is communication. Since the value of the telephone to the customer really is communication, then it is just proper focus on communication for the improvement of the product.

We can improve customer satisfaction depending on the kind of approach that we take. If we are product focused, like how developers in the past improved the telephone, then we might look at the item and come up with ways to make it a better product. Like we can have more exciting colors, change the dial to keyboard, make the cord longer, remove the cord, make it unbreakable, etc. These are features that customers will like if you asked them. However, if we focused on the function, i.e. “communication”, we will be treated to limitless ways of improvement. What are the ways to improve communication? Do we want to send him/her written messages? Do we want to send him/her a picture? Do we want to be able to communicate anytime-anywhere? Do we want to see the person we are talking to?

According to the VA/VE principles, function may be reduced to verb-noun description. Furthermore, cost of a function can be evaluated in order to bring out a solution that delivers the same function but with much lower cost. The VA/VE approach is also applicable in the processes of delivering the products or services. For example instead of saying “conveyor” let’s call the process step “move-box”, a verb-noun function description. There are many ways of moving a box: push manually, slide on an inclined plane, rotate a lazy Susan, or probably challenge the value of the function itself which is the first step in kaizen.

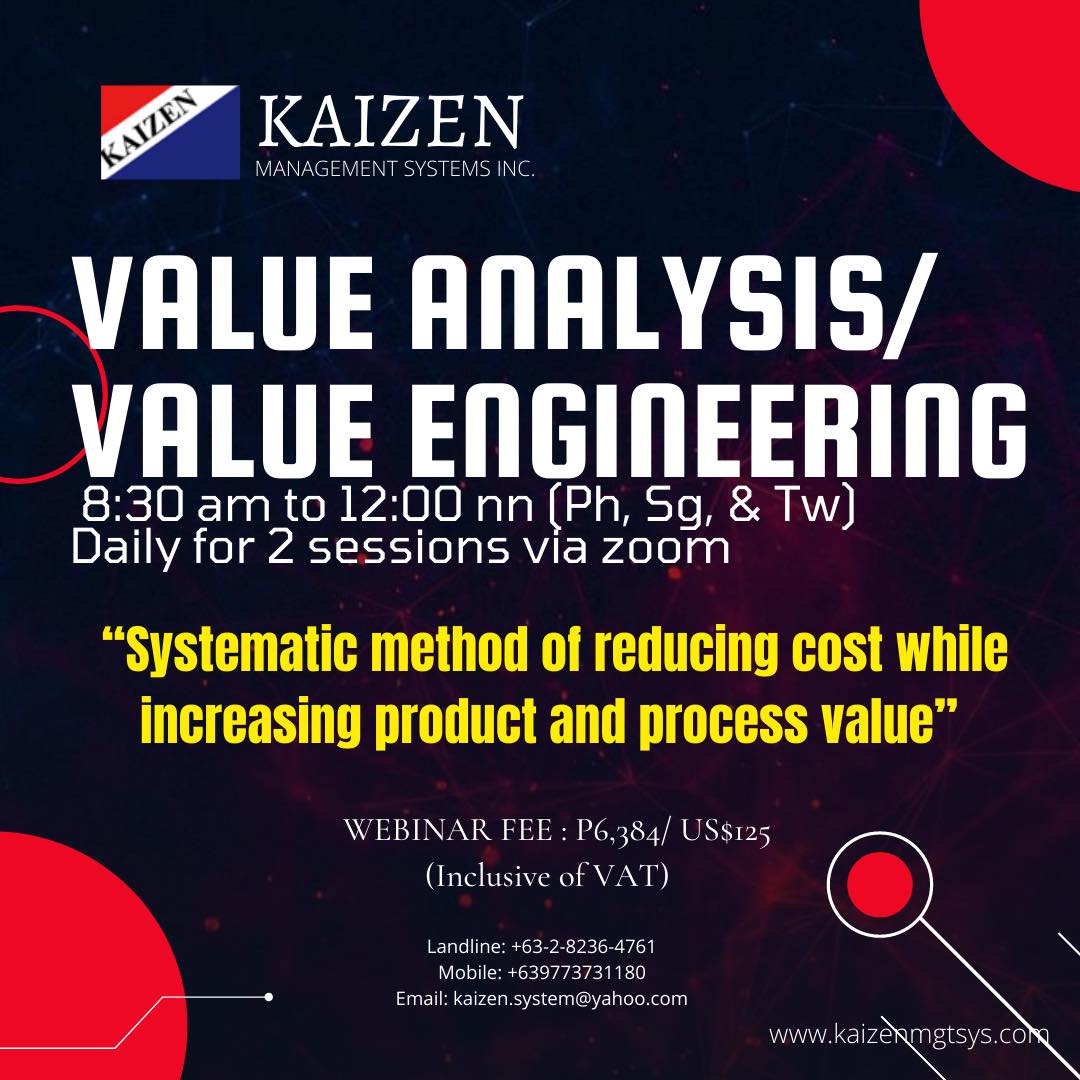

The company must explore improvement possibilities based on the functions or added functions. By the way, it would be very insensitive not to mention that sometimes value is not a working function but something that increase the salability or market price of the customer himself or herself. The main strategy of the company is to understand exactly what the customers want in terms of functions and value to them and find how they can deliver the processes or functions at the least possible cost. Our seminar on Value Analysis-Value Engineering (VA/VE) tell a lot more.

Improvement on Making the Customer Aware of Improvement efforts

What good does it do for the customer or the supplier if the customer doesn’t know that the later has improved his/her product or service? The answer to this question “is oftentimes nothing good happens” especially if improvement is not obvious. We owe it to ourselves to make sure that improvements are well communicated and the customers are aware of it. The customers need to know what improvements to “feel” and appreciate. Our customers will be happy to know that we are getting better and more capable of delivering their requirements. Our job as suppliers is to make sure that this is properly done so as not to be mistaken as self-serving but a way of creating customers awareness. It is also our job to make sure that this process of communicating improvement is also improving.

I think it should be a good idea to announce to our customers and market about our intentions and improvement plans, especially those that are directly affecting them. We have seen these happen with positive results because the company was successful in achieving it; and devastating results because the idea flopped. The effectiveness of announcements and advertisements can never be discounted. How many successful products are there largely because of TV commercials and billboards? Who knows about the good products that were not flaunted? Even politicians used it. National and even local candidates use all kinds of mass media including TV commercials and the Internet just for publicity. In the midst of information technology revolution (many of them still unexplored), we have all sorts of means to make our intentions and plans known to our market. Some of these are extremely low cost and even free.

Publicly announcing our improvement plans, oftentimes increases internal motivation for achievement. True, it will set heightened customer expectations but I believe it also pulls in support from them. It increases customer awareness, appreciation, improves relations, and probably will translate in increase in sales. Our customers are always searching for reasons why they should stick with us and communicating them our kaizen intentions will definitely create a positive impression. Once we tell them, our job is to make sure that sooner or later they feel the improvement in the direction that we said.

Improvement of the Goal Itself

Kaizen is not only improvement with respect to a goal but also improvement of the goal itself. The goal of the company must be continuously subject to improvement. (And we said that the most pragmatic goal of the company is profit.) The organization needs to be challenged and motivated to raise performance to keep it in fine fighting form. Aside from “fear” itself the next worst enemy of the company is complacency. Absence of a challenging goal, makes the organization sloth and complacent. The leaders of the company must raise the target (e.g. revenue or profit) significantly to keep people interested and motivated. Product redesign or new product introduction can also serve to create enthusiasm on people.

Some ideas for goal improvement challenges will be the following: increase market share, launch export initiative, research and development of new products and processes, new business acquisitions, acquire competitors, etc. A thought provocation challenge probably would be to include environment, social concerns and charity as part of your company’s goal.

Improvement of the Improvement System Itself.

A Kaizen company looks at the business as a long term concern. If this is the way we look at business, we will not act foolishly but responsibly. Even our strategy will change. Like, instead of saying that our business is “snacks food”, we might say that our business is our customers. Over a long period of time, needs of the customers change. If you stick on your own label of business you might lock yourself out of business. Kaizen means to continuously check the relevance of your business with respect to your customers. This leads us to thinking that our business must be customer-focused instead of “product-focused”. Being product-focused is dangerous nowadays. It has been a general knowledge that a giant company lose the mobile phone competition for focusing too much on the product more than it did on the customer.

It is absolutely necessary for the enterprise to understand exactly the specific customer needs that it is trying to serve. This is important to be able keep customers satisfied and happy. Our means to know about customers (what they want, why they buy, when they make buying decisions, how do we make us known to them) must be improved continuously.

Everyone is here to solve problems. The products and services we offer are all to solve problems. Every single product or service that people pay is a solution to a problem. We have to realize that we are all in the business of improvement i.e. there are problems out there and someone needs a solution that will make his/her life better. And since our business is problem solving or improvement it becomes obvious that we also have to improve our method of solving problems. Every company should realize that its business is not only to improve but also to improve the system that brings improvement.

Yes the improvement system must be improved. What do I mean by the improvement system (or Kaizen system)? Improvement system refers to the total scheme that includes: 1) suggestion of a kaizen idea, 2) evaluation and processing of the kaizen idea, 3) development of the kaizen idea into a project, 4) project implementation (might include funding), 5) development of new standards, and 6) project evaluation and correction. This whole system is the one that must be improved. For example, the suggestion system must be improved. Questions to ask might include the following: How do we improve the suggestion system? What is the current way of soliciting kaizen ideas? How do we improve participation in the suggestion system? How do we improve the quality of ideas? And how about improving the cycle time from idea suggestion to fruition? A continuously improving kaizen system or improvement system will always find ways to improve the process of improving and problem solving.

Limits of Improvement

Now let us dwell on the final question: Is there a limit to improvement or kaizen? The quick answer is yes – there is a limit to improvement of the product. That limit could be determined by any or all of the following: technology, customer satisfaction and economics. The technologies developed in the past 20-30 years are still being examined for potential applications yet more are coming at blinding speed. The accomplishments of science and technology are amazing. What used to be science fiction in the 70s are now realities staring at us. The rate of development has reached a point at which our mobile phones, for example, become obsolete before we can master all its functionalities. Even our manufacturing industries have become highly scientific in approach and language. What used to be millimeters in measure of tolerance has become microns and now they talk about nanometers. Despite its awe and wonders, science and technology have some limitations. We might embark on an improvement initiative to our product or process only to find that our effort “hits the wall” because the current technology hasn’t figured that out yet.

Yet many of our applications need not be high technology, which means that our customers might not be hi-tech or does not require it either. The level of customer appreciation can be the upper limit to our process or product improvement. What is the point of improving any further if the customer will not be capable of recognizing it? In one of my consulting visits, I had this conversation with a production manager who claimed that they control thickness tolerance to the tune of a few microns of their plastic film packaging product they’re making for a food company. So I replied that they must have precision thickness gaging instrument to do that. He said yes. Then I asked why they have to do it. He said they are concerned with the customer quality – the packaging material will not be able to hold if the film is too thin. “So does it mean your customer has precision gaging like you use?” He said no. “Do they have a third party doing the gaging for them?” He said no. “Then your customer will not be able appreciate your quality effort.”

If something is important to the customer, s/he will find a way to know that it is being done. In other words if the customer decided that thickness tolerance in microns is critical then they will have acquired a means of measuring in that level. But it seemed the customer didn’t want to get that far in measurement, therefore the improvement from the eyes of the customer wasn’t necessary.

On the second thought, may be I wasn’t told everything. I think the precision thickness control should be doing great improvement for the supplier more than its customers. If the supplier is able to pin down thickness tolerance to the narrowest band, then that is equivalent to excellent cost control. And that is improvement.

The last reason in my list that limits improvement is economics. The Quality Management Movement around the globe in the mid-1980s put so much emphasis on quality. So we heard slogans like “Quality is our business”, “Quality is an endless race where there are no winners, only front runners”, “Quality is everything” and the like. Now there has been a little toning down because people realized that quality is not everything after all. Industries have realized that they have to stop improving quality (like recovering a few defects per million) when it is no longer economical to do it because the cost of improvement eclipses the benefit that can be derived. And this applies to all aspects of business.