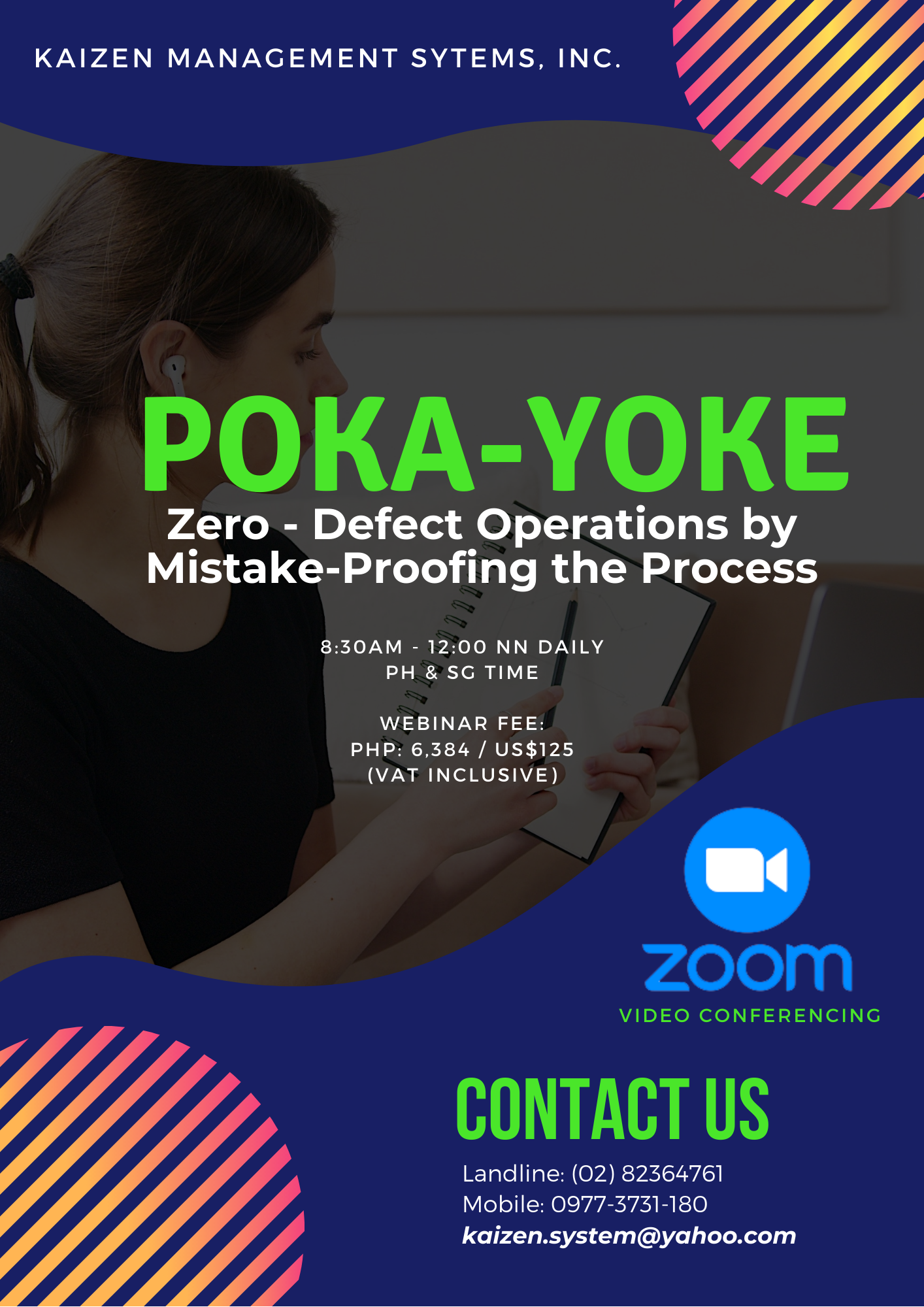

Poka-Yoke (PYK)

Zero-Defect Operations by Mistake-Proofing the Process

November 16-17, 2021 (8:30 AM-12:00 NN Daily)

This workshop will examine the nature and types of human errors involving human-machine interfaces and provide the approaches to eliminate or avoid them through system improvement. The facilitator will employ actual cases from personal experience and everyday examples to add to the effectiveness of the learning session. The power of this workshop is that, participants have testified how ideas and solutions came up even while the seminar was still going one.

Poka-yoke is Japanese for mistake proofing. It was first proposed in 1961 by Shigeo Shingo and developed by him as an integral part of the Toyota Production System. It is indispensable to achieving zero defects and enabling Just-in-Time production operations and Six Sigma initiatives.

Objectives: the end of this webinar, the participants will be able to:

- Understand the basic principles and concepts behind poka-yoke

- Apply these principles and concepts to the development of a poka-yoke solution to an actual operating problem.

Agenda:

- Introduction

- The Changing Business Environment

- The Primary Purpose of A Business Enterprise

- Process and Results

- Two Approaches to Dealing with Errors

- Inspection Techniques

- Three Strategies for Zero-Defects

- Different Kinds of Human Errors

- Sources of Ideas for Poka-Yoke

- Product and Process Design

- Eight Principles

- Next Steps

- Examples of Poka-Yoke

- Basic Poka-Yoke Functions

- Detection Methods

- Poka-Yoke Devices and Systems

Who should attend: Recommended for plant managers, operations managers, business owners, process engineers, product design and development specialists, industrial engineers, and other personnel directly involved in the design, production, and distribution of products or in service design and operations.

Please make check payable to

KAIZEN MANAGEMENT SYSTEMS, INC.

Account No: 001-473-0000-7473004042

Swift Code: MBTCPHMM

Cubao – Araneta Cyberpark, Quezon City

WEBINAR FEE: P6,384/ 125 USD (Inclusive of VAT) (digital pdf copy of the course manuals/workshop & certificate).

Time Frame: : 8:30 am – 12: nn daily (Ph & Sg Time) 1 day equivalent (2 webinar sessions of up to 4 hours each)

Methodology: Lecture , discussion, workshop/exercises, Q & A, and quizzes.

Online Requirements:

- Laptop, Smartphone or Tablet with Internet capability

- Zoom Apps

- Clean Internet access

RESOURCE SPEAKER: Jose S. Villegas : President of Kaizen Management Systems, Inc. is one of the founders of the Maintenance Association of the Philippines and became its president in 1992-93. Holds a Master of Engineering and BS Chemical Engineering degrees from Mapua Institute of Technology (MIT). He is an AOTS scholar on Production Management in Japan and trained in Energy Management in Korea and Japan and Maintenance Management in India. Mr. Villegas served in several companies in various technical and managerial capacities. Curious with a predisposition to problem solving, Joe is a course designer and in charged of R&D of KMSI. He facilitates and consults on Value Engineering, Product Design and Development, Six Sigma, Lean/Just-in-Time System, Kaizen, Cycle Time Improvement, SPC and TPM. He is currently pursuing his doctoral degree in Environmental Engineering at MIT.