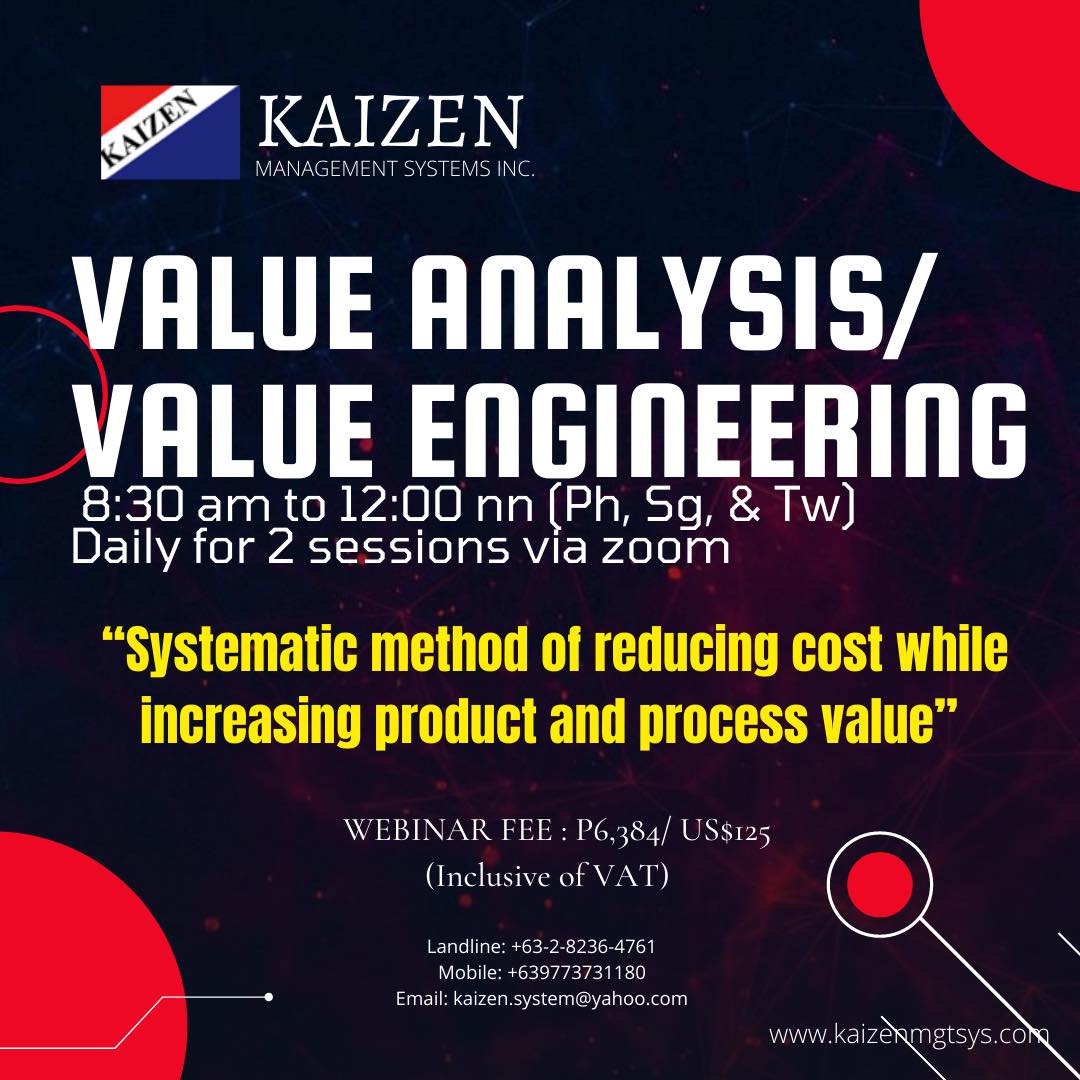

Value Analysis/Value Engineering (VAVE)

October 19-20, 2021 (8:30 AM-12:00 NN Daily for 2 sessions via Zoom)

Value Analysis/Value Engineering (VA/VE) has always been associated with product design. Little does everyone know that VA/VE can be a potent technique for process improvement as well as companies search for ways and means to reduce product cost in the process, VA/VE might just be the thing they are looking for.

The value of product or process is the lowest cost of providing a reliable performance of a function in particular and service in general. In real life, our products and processes are laden with lots of things and features that don’t add value but costs to the detriment of customers and end users. This seminar will clarify the issue of value and impart the techniques for identifying what is considered to be value and what is waste from the point of view of the customer. Moreover, it will teach the techniques of creating more value (in the process) for the customer and the systematic elimination of process wastes. The seminar will deal mostly on process VA/VE, although product VA/VE will be discussed just the same.

Objectives:At the end of the webinar, the participant would have acquired the following:

- Review of the fundamental concept of value in products and processes.

- Techniques to identify and analyze process wastes and non-value adding features in process and products.

- Techniques for eliminating non-value adding activities in processes.

Agenda:

- Value Analysis

- Function Analysis

- Product Design Improvement

- Intro to Function-Cost Matrix

- Function-Cost Matrix Workshop VA/VE in Process

- Using your brain

- 7Muda and 3Mu

- Shapes of VA/VE Solutions

- Muda Eliminations

- Kaizen & VA/VE

Who should attend: This webinar will be best for Product Designers, Production Engineers & Managers, Industrial Engineering, R & D, Process Audit; Improvement Teams, Maintenance & Engineering, and Training.

Please make check payable to

KAIZEN MANAGEMENT SYSTEMS, INC.

Account No: 001-473-0000-7473004042

Swift Code: MBTCPHMM

Cubao – Araneta Cyberpark, Quezon City

WEBINAR FEE: P6,384/ 125 USD (Inclusive of VAT) (digital pdf copy of the course manuals/workshop & certificate).

Time Frame: 8:30 am – 12: nn daily (Ph & Sg Time) 1 day equivalent (2 webinar sessions of up to 4 hours each)

Methodology: Lecture, discussion, workshop/exercises, Q & A, and quizzes.

Online Requirements:

- Laptop, Smartphone or Tablet with Internet capability

- Zoom Apps

- Clean Internet access

RESOURCE SPEAKER: Jose S. Villegas : President of Kaizen Management Systems, Inc. is one of the founders of the Maintenance Association of the Philippines and became its president in 1992-93. Holds a Master of Engineering and BS Chemical Engineering degrees from Mapua Institute of Technology (MIT). He is an AOTS scholar on Production Management in Japan and trained in Energy Management in Korea and Japan and Maintenance Management in India. Mr. Villegas served in several companies in various technical and managerial capacities. Curious with a predisposition to problem solving, Joe is a course designer and in charged of R&D of KMSI. He facilitates and consults on Value Engineering, Product Design and Development, Six Sigma, Lean/Just-in-Time System, Kaizen, Cycle Time Improvement, SPC and TPM. He is currently pursuing his doctoral degree in Environmental Engineering at MIT.