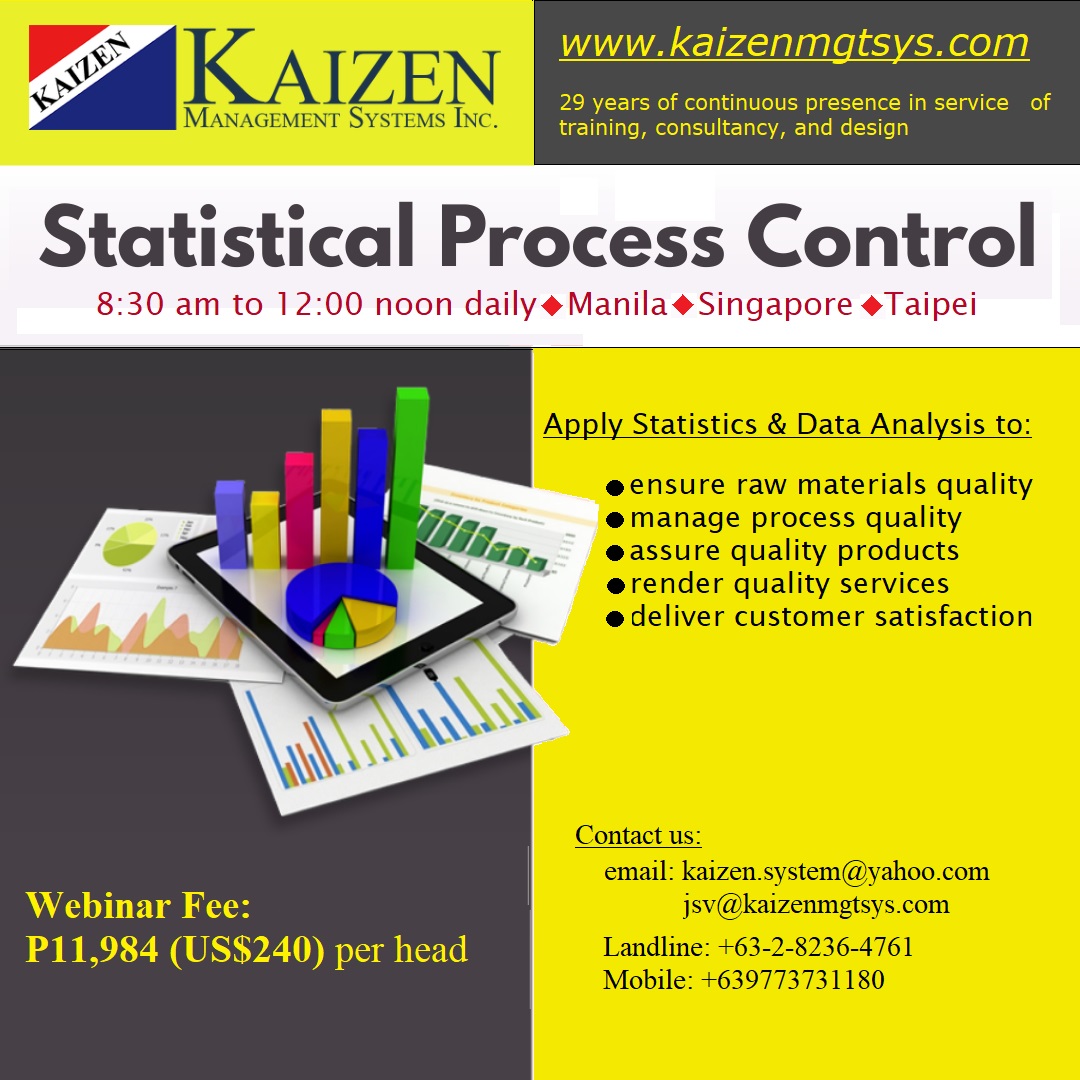

Statistical Process Control (SPC)

October 12-15, 2021 (8:30 AM-12:00 NN Daily for 4 sessions via Zoom)

Variations are common in nature and in industries. Customers abhor too much variability, in fact, the ability of a provider to predictably deliver uniform products and services is an indication of good quality. However, customers have accepted variations to be a fact of life so tolerances have been put in place. Processes can be controlled so that the resulting product or service doesn’t violate the customers’ tolerable measures. Statistical process control is an initiative to establish measure, monitor and control process performance (variability included) through the application of statistics. It attempts to detect abnormalities early enough in order to eliminate assignable causes that result in product defects.

Completion of course earns the participant 20 points credit for Kaizen-6 Sigma Green Belt and Black Belt Certification.

Objectives: By the end of the webinar, a successful participant will be able to:

- Explain the basic concepts & principles of statistics, probability, variation, measurements & control, such these can relate to their work situations;

- Elucidate on the basic principles behind statistical process control and process capability studies;

- Interpret quality reports and apply statistical tools and techniques in solving quality and design issues; and

- Develop statistical tools applicable to his/her company.

Agenda:

- Fundamentals of Quality Control

- Basic Statistics

- Concepts & Theories of Probability

- Theory of Variation

- The Concept of Measurement

- Acceptance Sampling

- Mil Std 105-E

- Sampling

- Histogram

- The Normal Curve

- Control Charts

- Process Capabilities & Tolerances

- SPC Management

- Introduction to Six Sigma Quality

- Problems & Cases

Who should attend: Prospective Kaizen-Sigma Green and Black Belts, Managers, Supervisors, Foremen, & Staff in Production; QA/QC; Industrial Engineering, R & D, Kaizen Teams, Maintenance & Engineering, & Training Departments

Language to be used: English

Please make check payable to

KAIZEN MANAGEMENT SYSTEMS, INC.

Account No: 001-473-0000-7473004042

Swift Code: MBTCPHMM

Cubao – Araneta Cyberpark, Quezon City

WEBINAR FEE: P11,984 / US$240 (Inclusive of VAT) (digital pdf copy of the course manuals/workshop & certificate).

Time Frame: 8:30 am – 12: nn daily (Ph & Sg Time) 4 webinar sessions of up to 4 hours each

Methodology: Lecture, discussion, workshop/exercises, Q & A, and quizzes.

Online Requirements:

- Laptop, Smartphone or Tablet with Internet capability

- Zoom Apps

- Clean Internet access

RESOURCE SPEAKER: Jose S. Villegas : President of Kaizen Management Systems, Inc. is one of the founders of the Maintenance Association of the Philippines and became its president in 1992-93. Holds a Master of Engineering (IE) and BS Chemical Engineering degrees from Mapua University. He is an AOTS scholar on Production Management in Japan and trained in Energy Management in Korea and Japan and Maintenance Management in India. Mr. Villegas served in several companies in various technical and managerial capacities. Curious with a predisposition to problem solving, Joe is a course designer and in charged of R&D of KMSI. He facilitates and consults on Value Engineering, Product Design and Development, Six Sigma, Lean/Just-in-Time System, Kaizen, Cycle Time Improvement, SPC and TPM. He is currently pursuing his doctoral degree in Environmental Engineering at Mapua University.