In time for our 25th celebration, Kaizen Management Systems, Inc., a Manila-based training and consulting firm will be conducting a series of seminars and training in Cebu in September to November 2017. We would like you to join us in planning this event.

| Date(s) | Training/Seminar Title | No. of Days | Fee* |

|---|---|---|---|

| Oct 2 | Why-Why Analysis | 1 | P4,950.00 |

| Oct 2-3 | Project Management | 2 | P9,350.00 |

| Oct 2-3 | Kaizen Leadership Strategy | 2 | P9,350.00 |

| Oct 18-19 | Total Productive Maintenance | 2 | P9,350.00 |

| Oct 4-5 | Lean Manufacturing & Just-In-Time System | 2 | P9,350.00 |

| Oct 6 | Poka-Yoke (Mistake-Proofing) | 1 | P4,950.00 |

| Oct 16-17 | Maintenance Management | 2 | P9,350.00 |

| Oct 9-10 | Design of Experiments | 2 | P9,350.00 |

| Oct 18 | Failure Mode & Effect Analysis | 1 | P4,950.00 |

| Oct 21 | Advanced 5-S | 1 | P4,950.00 |

| Oct 11 | 8-D of Problem Solving | 1 | P4,950.00 |

| Oct 20 | Measurement System Analysis | 1 | P4,950.00 |

| by special request | Problem-Solving Process & Tools | 2 | P9,350.00 |

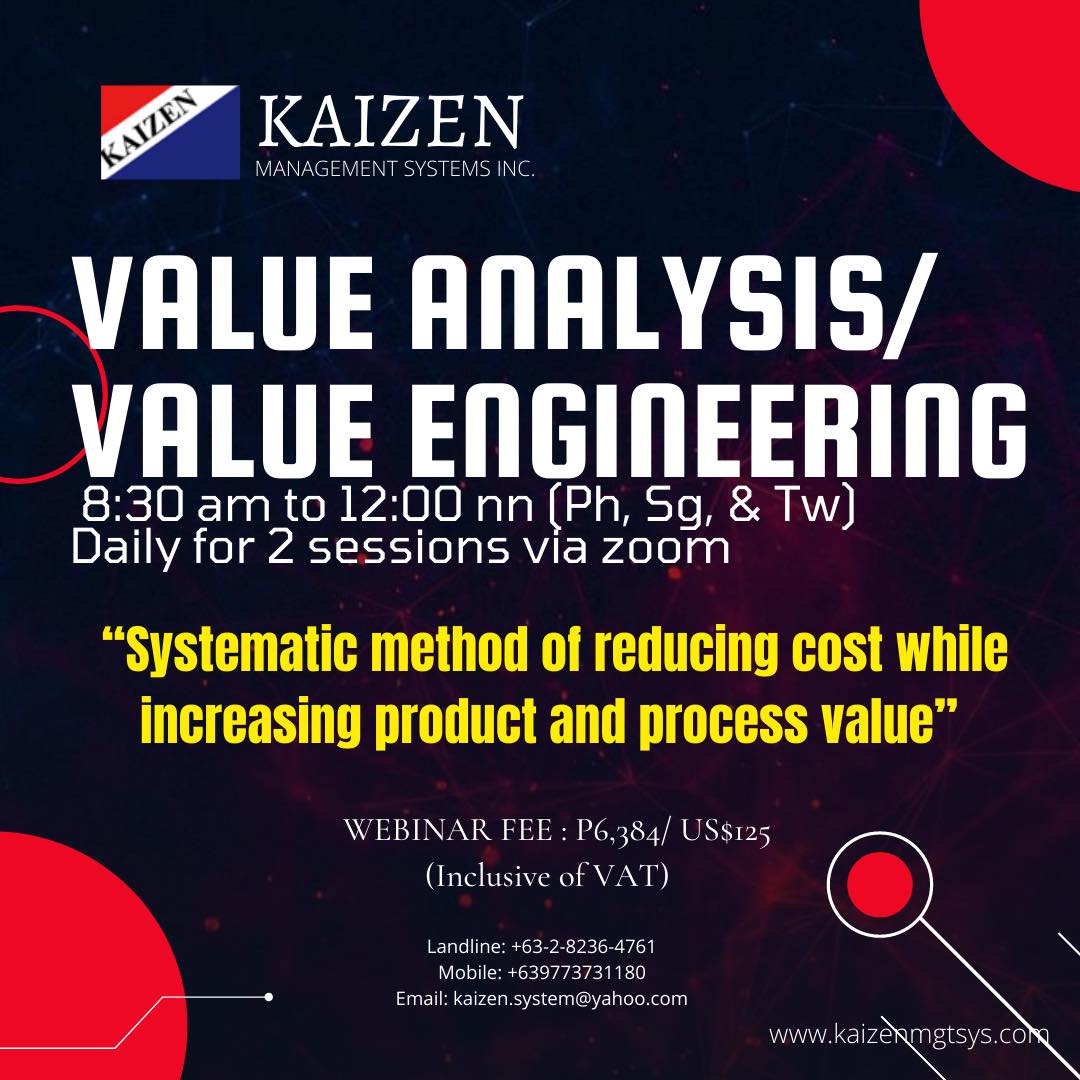

| by special request | Value Analysis/Value Engineering | 1 | P4,950.00 |

| by special request | Lean Inventory System | 1 1/2 | P7,700.00 |

| by special request | Training the Trainer | 1 1/2 | P7,700.00 |

| by special request | Technical Writing & Documentation | 2 | P9,350.00 |

| by special request | Supervisory Leadership | 2 | P9,350.00 |

| Oct 20-21 | Statistical Process Control | 2 | P9,350.00 |

| by special request | ISO 9001:2015 Awareness & Documentation | 2 | P9,350.00 |

Venue: Cebu Waterfront Hotel

Why-Why Analysis

techniques to accurately pinpoint the root causes of the process problem or a machine phenomenon.

Lean Manufacturing &

Just In-Time System

features the Kaizen approaches and techniques for improving quality, cost & delivery.

Kaizen Strategy

imparts the process of creating a corporate culture of continuous improvement through people.

Maintenance Management

imparts the system and practices that improve equipment availability and maintenance cost.

Total Productive Maintenance

improving overall equipment effectiveness through maintenance-production cooperation.

8-D of Problem Solving

presents the team approach in resolving customers complaints though systematic problem solving.

Problem Solving Process & Tools

features systematic approach to problem solving process and proven problem solving tools.

Poka-Yoke (Mistake Proofing)

imparts the mistake-proofing approaches on human errors in service/production work.

Design of Experiments

imparts the statistical approach of designed experiments for efficient process improvement.

Measurement System Analysis

addresses the measurement system error to attain gauge repeatability & reproducibility.

ISO 9001:2015 Awareness & Documentation

proactive and risk-based quality standardization process under ISO 9001:2015

Failure Mode & Effect Analysis

technique of identifying, prioritizing and addressing potential product/process failures.

[google_maps id=”4155″]