By Jose S. Villegas* – Kaizen Management Systems, Inc.

It was mentioned in the last editorial that corporations can last for hundreds and even thousands of years. There are companies, still living, that are more than one thousand years old. So companies therefore unlike humans can be eternal. Thus among others, it was suggested that corporations: 1) must plan for eternity; 2) engineer and develop a culture of honesty and loyalty for good business; 3) have a culture of continuous improvement or endless effort to seek the “truth”; and 4) adapt to changing market. This last one mentioned requires visions and strong leadership.

Compared to the lifespan of a company (we said can be eternal), visions are rather finite. They are not sharp definitions of time. They are just how much time the eyes can see. Visions are conditions that we want to see at some time in the future. Visions have horizons and when reached, new visions must be searched. For a company to be continuously dynamic and relevant, it must continuously reestablish visions over time.

This article will present that the best formula for success is visionary leadership and kaizen culture combined. Two cases will be featured: Henry Ford as a the powerful visionary leader behind Ford Motor Company and Toyota Motor Company an example of a successful company that is both “vision led” and having a favorable kaizen culture. In the end, we will present analysis and recommendations about companies should do.

Visions

In the early 1960s, the automobile industry was one of Japan’s least competitive industries in the international arena. Toyota as a company, saw the vision of itself as a major global player in the car business. It embarked on a program that lowered production costs and developed even more sophisticated cars, while at the same time achieved the highest possible level of quality in production. We all know this today as the Toyota Production System (TPS). It is unclear though if there is a single person to whom the TPS can be attributed to. However, many people believe that Taiichi Ohno was mainly responsible for the development of the Toyota Production System. Anyhow, the Japanese have been known to act as one corporate body and plurality of leadership.

The American Automotive industry was being eroded by Japanese carmakers in early 1980s. Chrysler was the biggest loser among the Big Three. Lee Iacocca, President of Chrysler pursued the vision: get the Americans back to patronize American-made cars (instead of the Japanese brands). He was able to get the Federal Government to authorize a $1.5 B loan guarantee for Chrysler to recover. And Chrysler did!

Back in 1983, Steve Jobs saw that the personal computers will be the in-thing after cars as he said these words to Pepsi’s John Sculley trying to convince him to become CEO for Apple: “Do you want to spend the rest of your life selling sugared water to children, or do you want a chance to change the world?” We all know that during that time the vision that Jobs followed was “A computer in every home”.

These visions were seen and established by leaders served as inspirations for companies and organizations to succeed and achieve feats others can only watch in awe. When leaders stop seeing visions, companies start to decline. Visions are for companies as destinations are for ships.

Visions are of higher order than objectives. The relationship between an objective and vision is that objectives are established based on visions. It is possible though to have an objective without a vision but this one will be short-lived and void of a long term foundation.

Visionary Leaders

Visionary leaders are a different breed of leaders in that they did not only see the visions but also able to establish the means of achieving them. Visionary leadership is not only being able to make others follow but showing people a better place to be and the way to get there. It is not a narrow-minded pursuit of the vision. One such person is Henry Ford.

Henry Ford – The Visionary Leader

About one hundred years ago, the “horseless carriage” or motor car was just being introduced to the world. There were no real roads, no gas stations and only the super rich can afford a car. It was during this time that Henry Ford, son of a modest Michigan farmer, had a vision: “Car as the ordinary man’s utility rather than as the rich man’s luxury.”

About one hundred years ago, the “horseless carriage” or motor car was just being introduced to the world. There were no real roads, no gas stations and only the super rich can afford a car. It was during this time that Henry Ford, son of a modest Michigan farmer, had a vision: “Car as the ordinary man’s utility rather than as the rich man’s luxury.”

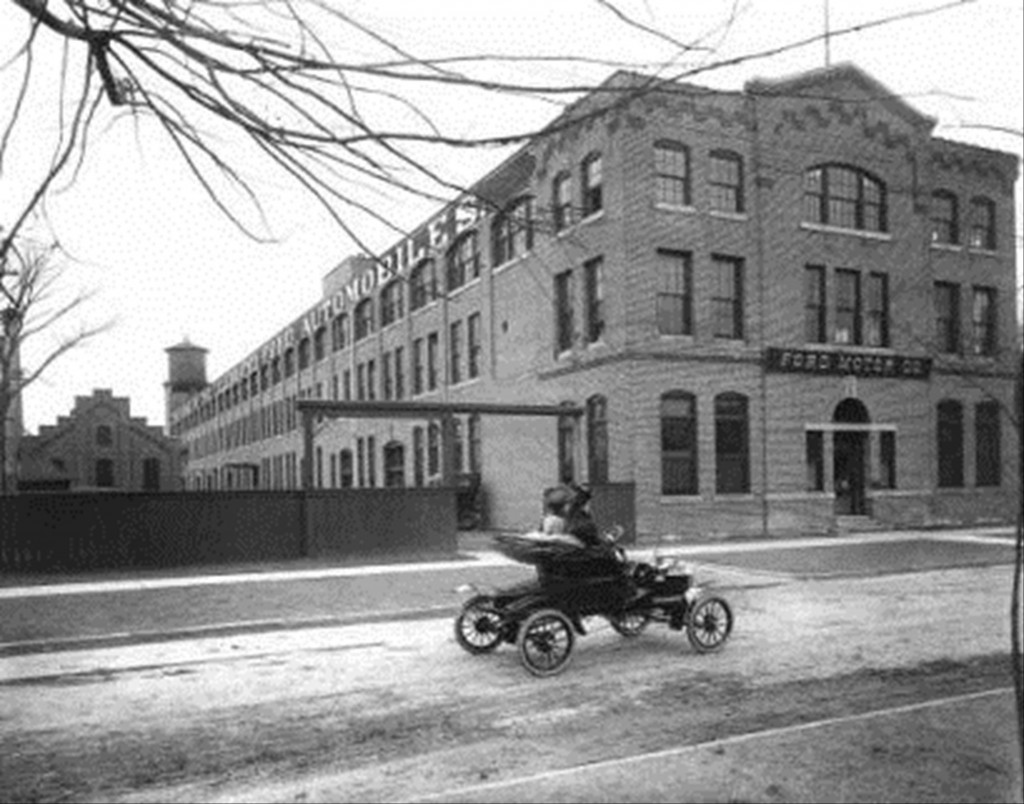

Ford’s Model T

Ford’s great strength was the manufacturing process — not invention. Long before he started a car company, he was an inveterate tinkerer, known for picking up loose scraps of metal and wire and turning them into machines. In 1903, after a being able to make several motor cars on a personal enterprise, he founded Ford Motor Company with several individuals. The company was a success from the beginning.

By 1908 (officially October 1, 1908), Ford came out with several models including “Model T” which was being produced at 100 units per day. The stockholders were ecstatic (as the company was already making a lot of money) but Ford was dissatisfied and looked forward to turning out 1,000 a day. He was quoted as saying “I will build a motor car for the great multitude” and insisted in using profits gained from Model T to improve the assembly line (which he developed) and the production system. As 58.5% owner of the Ford Motor he was unstoppable in his improvement efforts to reduce the price per unit. And finally, the only way the minority stockholders could do to protect their dividends and stop Ford on what they claimed as reckless expansion was to take him to court. The court decided in favor of his adversaries and losing, Ford, decided to own the whole company by gobbling up the shares of all the other owners in the tune of more than $100 million, the most lucrative buy out in those days. Thus in 1920, never had one man controlled so completely a business enterprise so grand.

“In simple terms, the Model T changed the world. It was a powerful car with a possible speed of 45 mph. It could run 25 miles on a gallon of gasoline. It carried a 20-horsepower, side-valve four-cylinder engine and two-speed planetary transmission on a 100-inch wheelbase. Important to the long-term success of the Model T was Childe Harold Wills’ experimentation with the properties of vanadium steel, which resulted in the lightness and durability that was an important trademark of the Model T.”

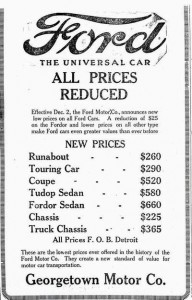

The black Model T was initially passed on to customers at a price of $825 in 1908 but in 1924 it was down to $260 making it America’s Everyman’s car. Ford and his engineers continuously developed the car manufacturing technology, finding ways not only to reduce cost but also to speed up production as fast as people can buy them. By 1913 at Ford’s new plant in Highland Park, Michigan, on a constantly moving main assembly line, parts and sub-assemblies were added in a precise timing that a complete car was turned out every 93 minutes. Indeed, Ford, instituted industrial mass production but what really mattered to him was mass consumption.

Ford invented the dealer-franchise system to sell and service cars. In the same way that all politics is local, he knew that business had to be local. By 1912 there were 7,000 Ford dealers across the country.

Ford figured out that if he paid his factory workers a real living wage and produced more cars for less money, everyone would buy them. Thus, in 1914, when wages was based on the lowest that workers would take, he increased the minimum wage of his workers to $5.00 a day of eight hours. The prevailing minimum wage that time was $2.34 for a nine hour-day. Ford became a world-wide celebrity and people praised his humanitarianism and social concerns while others excoriated him as a mad socialist who caused the forced widespread of minimum wage increase to the horror of capitalists.

His vision would help create a middle class in the U.S., one marked by urbanization, rising wages and some free time in which to spend them. When Ford left the family farm at age 16 and walked eight miles to his first job in a Detroit machine shop, only 2 out of 8 Americans lived in the cities. By World War II that figure would double, and the affordable Model T was one reason for it. People flocked to Detroit for jobs, and if they worked in one of Henry’s factories, they could afford one of his cars — it’s a virtuous circle, and he was the ringmaster. By the time production ceased for the Model T in 1927, more 15 million units had been sold – or half the world’s output.

“One hundred years ago, business was done by virtual dictators — men laden with riches and so much power they could take over a country if they wanted to. That’s not acceptable anymore. But if it hadn’t been for Henry Ford’s drive to create a mass market for cars, America wouldn’t have a middle class today.” – Lee Iacocca

Issues & Problems During Ford’s Time

Manufacturers today worry about high materials and parts prices but Ford’s problems were a lot more challenging. While he was driving the cost of production down, raw material prices were not only getting high but were in short supply partly because of World War I and generally because of the increasing demand from all industries.

Early on, Ford recognized the importance of just-in-time deliveries. Wheels, tires, upholstery, and various accessories were purchased from other companies around Detroit. However, as Ford production increased, these smaller operations had to speed up their output; most of them had to install their own assembly lines but they couldn’t keep up with the increasing demand. Coordinating production and shipment so that each product will arrive at the right place and at the right time was next to impossible. At first Ford tried accumulating large inventories to prevent delays or stoppages of the assembly line, but he soon realized that stockpiling wasted capital. Instead he took up the idea of extending his business to cover the entire supply chain. He reasoned that his costs in manufacturing began the moment the raw material was separated from the earth and continued until the finished product was delivered to the customer.

Ford’s Solutions

The plant in River Rouge embodied his idea of an integrated operation, encompassing production, assembly and transportation. To complete the vertical integration of his empire, he purchased a railroad, acquired control of 16 coal mines, and about 285,000 hectares of timberland, built a sawmill, acquired a fleet of Great Lakes freighters to bring ore from his Lake Superior mines, and even bought a glassworks. At this plant, every 8 o’clock in the morning, just enough ore for the day would arrive on a Ford freighter from Ford mines in Michigan and Minnesota and would be transferred by conveyor to blast furnaces and transformed into steel with heat supplied by coal from Ford mines in Kentucky. It would continue on through the foundry molds and stamping mills and exactly 28 hours after arrival as ore would emerge as a finished automobile. Similar systems handled lumber for floorboards, rubber for tires and so on.

At the height of its success, the company’s holdings stretched from the iron mines of Northern Michigan to the jungles of Brazil, and it operated in 33 countries around the globe. Most remarkably, not one cent was borrowed to pay for any of it. It was all built out of profit from the Model T.

In much the same fashion, he worked on making sure that an automotive infrastructure developed along with the cars. Just like horses, cars had to be fed — so Ford pushed for gas stations everywhere. And as his car wheels bounced over the rutted tracks of the horse age, he campaigned for better roads, which eventually led to an interstate-highway.

Ford as a Leader

As a leader, Ford was benevolent and his paternalism is admirable. At one point, he was so worried that his workers would go crazy with their five bucks a day that he set up a “Sociological Department” to make sure that they didn’t squander the money on booze and vice. He banned smoking because he thought, correctly as it turned out, that tobacco was unhealthy. “I want the whole organization dominated by a just, generous and humane policy,” he said.

He was violently opposed to labor organizers, whom he saw as “the worst thing that ever struck the earth,” and entirely unnecessary — who, after all, knew more about taking care of his people than he?

The problem was that for too long Ford worked on only one model. Although people told him to diversify, Henry Ford had developed tunnel vision. He basically started saying “to hell with the customer,” who can have any color as long as it’s black. He didn’t bring out until the Model A in 1927, and by then GM (a conglomerate of independent carmakers) was starting to take form.

In a sense Henry Ford became a prisoner of his own success. He turned on some of his best and brightest when they launched design changes or plans he had not approved.

Observations and Lessons

On the basis of Henry Ford’s story, the following observations and lessons may be drawn:

- A vision is the shape of what can be. Ford saw that the motor car can be affordable by ordinary people and therefore he can sell a lot of them. He knew in his heart that the motor car can be made cheap. He foresaw the development of an ideal car (later known as Model T).

- A vision includes the means to achieve itself. Ford saw that the way to realize his vision of making the car affordable was through effective design, efficient production system and mass production. For Ford, it was not enough that thousands of cars were on the roads, he wanted everyone to be able to afford and buy a car. He wanted millions of them out there. He used the profits made in Model T to solve all the production problems and bring down the price of car. He hired the best engineers to help him improve his production system and assembly lines. He also devised the dealer-franchise system to localize the sales and service of cars.

- A vision is for the future but may not have definite frame in time. It was evident that in Ford’s case he was only sure that his vision and the means to achieve it was possible but didn’t know exactly when. But he did not stop improving his design (until he developed Model T) and its production system until Model T was made obsolete by the competition.

- A visionary leader has a clear understanding of the issues his vision are addressing and the issues that the vision might create. It was evident that Ford understood that people like cars but the main issue was its affordability. He understood as well that there were not enough suitable roads and gas stations. There were no real parts suppliers. There was no automotive industry. So he pushed hard for a massive program of road building and helped develop part suppliers. (Gas stations came up on their own.) It is interesting to note that Ford’s vision also created issues and problems. Automobile was such a big machine with parts that were big and expensive. Mass producing it required a large factory with expensive and huge equipment plus the stupendous amount of working capital in terms of labor, materials and parts. Ford knew all these. He started small and in order to arrive at a scale he thought would be significant, he continuously enlarge both the factory and production volume through the profits made from the business itself. Ford was probably the first man on record to conclude that too much inventory is evil and wasted capital. He solved delivery and cost issues by vertically integrating the whole business of making cars. He was so successful that 1927, Ford Motor Company was the biggest manufacturer in the world, making half of the global automobile requirement. Ford did it not from borrowing money but from the fruits of his vision.

- A visionary leader may not be the paradigm shifter but he is a paradigm pioneer. Henry Ford didn’t invent the motor car but his drive to develop and sell millions of them changed the world. He solved all the major problems of mass producing cars one by one and mastered the tricks of the business. In his heyday, Ford was in the forefront of development. All design changes must pass his approval. His obsession to his vision resulted to massive changes in the society that elevated the economic life of ordinary workers and created a strong middle class in the United States.

- A visionary leader must possess a strong determination (or obsession) to realize his vision. He must set the examples of a good follower as he himself has someone to follow: his own vision. When his company was already making 100 cars a day and thus plenty of profit, Ford’s associates’ were happy and satisfied but he wasn’t. He knew that he was on his way but had not arrived yet. He knew that there was yet a long way ahead. And this was the reason why he could not be stopped, despite the persuasion for him by his colleagues to cease from using the profits to fund further development. The culmination of his vision was the integrated River Rouge Plant complex which showcased the ideas of the great visionary leader.

- A visionary leader must possess an excellent communication ability to sell the idea behind the vision and to get followers. Ford communicated his vision through his words, decisions and actions. Despite seemingly difficult financial standing when he was still starting, he never stopped developing and improving his car until he found Model T. People around him understood his message although not everyone agreed with him. In his desire to make the car affordable, he did not only tried to reduce the production cost but also doubled the daily wages of auto workers so they too can afford the cars they were making. His effort to increase wages was not limited to his own company; he pushed for a nationwide increase in wages. And this was all for people to have money to buy his cars. When he was alive he was well-known to be a generous and humanitarian businessman popular to the masses and his very own auto workers adored him.

- A visionary leader knows how to motivate and reward followers. Motivating, recognizing and rewarding followers are marks of great leaders. Visionary leaders know human nature and understand that they need support from followers as they pursue their visions. The first human nature that Ford understood is that men would like to own cars. He was generous, benevolent and caring to his people. During his time the greatest motivation to people seemed to have to do with economics and wages. Ford was able to satisfy that need. His company gave a daily wage more than twice other companies pay their workers. Young men from the farm would go to the city hoping to work in one of Ford plants. Because if they did, they will make good money and that can buy them cars too.

Visionary Leader and the Company

Visionary leaders cannot realize the vision alone. S/he needs warm bodies to make his/her vision happens. But what kind of organization is ideal for successful implementation of the vision?

Visions are usually blurred and lacked colors and details. As the visionary leader gets nearer and the view gets closer, s/he sees the same vision to be a little different. Reality checks oftentimes become necessary which also might require the vision to be reviewed and re-stated. When this happens the whole program will require a corresponding review and refinement and the whole organization must be flexible enough to accommodate the changes.

It is not always the visionary leader who is the one seeing the changes in the vision. Sometimes the organization or someone outside of it (a customer perhaps) may be the one discovering that the necessary conditions have changed and therefore the program of solution must be re-aligned. Success depends on an active partnership and cooperation between the visionary leader and the company or organization. The organization must be flexible and willing to learn new things and make implementation refinements.

Kaizen or Continuous Improvement Culture

Kaizen Management Systems, Inc. (KMSI) defines Kaizen as continuous improvement of people, processes and products involving the whole organization. Kaizen is a top-down total system improvement orchestrated by the Chief Executive Officer.

There are two kinds of kaizen: namely: Kaizen (with a capital “K” and not in italics) as defined by KMSI and the generic kaizen. The generic kaizen can be equated to improvement as people know it. It is also known as the attitude of a person of doing better today than yesterday. If the company does not manage the change process and instead everybody does kaizen, the danger is that the improvement activities may not be aligned and focused. In this case, the sporadic improvement activities will not be able to attain synergy and worst may even cancel each other’s effects. What companies need to practice is Kaizen in which the theme of improvement is ordered from the top. There should always be someone watching from the top to see what improvements are needed and where. This way, improvement will be on areas that are necessary and being such will not be that costly. The Theory of Constraints (of Eliyahu Goldratt) say that in reference to the goal of a system, system components are not equal in capacity, others may need more improvements whereas others may not need improvements at all but may even have to tone down performance. It is the component with the lowest capacity that limits the system’s ability to meet its goal. So someone must be able to see the total system situation and be able to feedback to the operating components how they do and how they should react. Improvement is administered where it is most needed.

KMSI suggests that Kaizen and kaizen be adopted by the company. The management must inculcate the value of kaizen to every employee. If most (if not all) of the employees are practicing kaizen and have adopted it as a way of life, then you have a kaizen culture. It will be easier to implement the Kaizen Strategy if a kaizen culture exists in the company.

Kaizen Strategy proposes that a company should do three things namely: “maintenance of business”, Kaizen, and innovation. This means that while the company maintains standards, it is also improving at the same time. Improvement can come by way of Kaizen or incremental improvements that involve everyone or big improvements called innovation.

Companies that practice Kaizen, adopt certain attitudes or framework of thinking. These are:

- Total System Focus – A Kaizen organization will always review the effect of efforts on the total system. This means that improvement projects and initiatives must result to a positive impact on the bottom line. Finding the total system weakness is not something that a Kaizen organization does in relation to a plan, but often times it is the deliberate effort of finding system weakness that leads the organization to plan for improvement.

- Process and Results Thinking – Everybody understands that it is in working hard on the process that makes for favorable results. It is a discipline to actively discover how to do it right in the process rather than to make correction later on the result if found to be unsatisfactory. And will continue to refine the process until a satisfactory result is accomplished.

- Non-blaming/Non-judgmental – A Kaizen company must be supported by people who are not driven by fear but are encouraged to bear witness to system weakness. A blaming and judgmental management will discourage people from reporting problems for fear of being punished. In a Kaizen company, problems are regarded as system imperfection and therefore must be addressed if only to improve the system.

These Kaizen super-ordinate principles or mental framework are not everything. They have to be supported with cultural practices. One such practice is looking at problems as opportunities. Nobody wants to be in a problematic situation or crisis but if it does, a Kaizen company will always take the challenge and try to figure out how to overcome it. “Having no problem is the biggest problem of all” according to Taiichi Ohno of Toyota. He further said that “If a problem is left unsolved and the supervisor is uninformed, neither kaizen nor cost reduction can be applied. When there is trouble, stopping the machine means also identifying the problem. Once the problem is clear, kaizen becomes possible.” For this reason, “asking why 5 times” or asking “why” continuously is practiced by everyone for the purpose of knowing the root cause(s) of a problem which must not be left unresolved.

Kaizen companies also standardize solutions or newly discovered ways of doing the business. They believe that every unit of improvement must make its way into the system or the organizational habit. However, in these companies, standards are meant to be broken. In other words, a standard is only good as long as the new one has not been put into existence yet. Kaizen organizations believe that the best, cheapest, fastest, and safest results are realized by anticipating problems and solving them in advance during the process or even during the design and development of the product or the process. The exact opposite of “upstream management” is waiting for the defects to happen and correct them.

Kaizen companies understand that they exist for and have a strong sense of love and responsibility for their customers. They treat a customer as someone especial. They establish long term relations with their customers and keep them for good. All those outside of them buying their products are customers and they extend this definition to people inside the company as well. That is why the next process is also and must be treated like a real customer. By being kind to the next process, quality is assured from beginning to end.

They are not only good to the next process but also to the “Previous Process”, the “supplier”. These companies treat their suppliers as part of their system, as someone who is doing service or favor for them, not someone they are doing favor to.

Culture Can Also Be A Vision

The good news about culture is that based on our observations and experience of our clients, culture can change and it can be developed. The leadership can visualize the kind of future organizational attitude it wants to see and establish a long term plan that will allow the development of the kind of culture appropriate to the business of the company and consistent with the expectations of the society to the company. Such a plan includes the features of the culture the ones outlined above. More importantly, how the top management must set the example and drive the practice of the desired traits over a long period of time that may be beyond the tenure of some of them.

An example of a visionary company that developed a kaizen culture is Toyota Motor Company.

Toyota Motor Company

The company started out as a machine and loom factory called Toyoda Automatic Loom Works, Inc. It was founded by Sakichi Toyoda in 1926. In 1933, the automobile division was created and led by Sakichi’s eldest son Kiichiro who developed his first prototype car in 1935 called Model AA Sedan. The department spun out of the company in 1935 as Toyota Motor Company.

When Toyota started, General Motors and Ford were already running assembly operations in Japan. Toyota and other Japanese car manufacturers were not known to be competitive and their cars were even taunted overseas as copies and junkies. Unperturbed, the new company grew and its leaders envisioned that Toyota was going to make fuel efficient automobiles considering Japan’s situation of having no petroleum and lacking other natural resources.

At a private opening ceremony for the Koromo Plant on November 3, 1938, Kiichiro pledged his commitment to building a great automobile industry. While addressing the officers and employees of the then young Toyota Motor Co., Ltd., he encouraged everyone to fulfill their own responsibilities for themselves and for the good of the company:

“Neglect your duties and you’ll bring ruin upon yourselves; fulfill your responsibilities and you’ll find yourselves enhanced. If each person makes the most sincere effort in his assigned position, the entire company can achieve great things.”

In 1938, Just-In-Time System was put in place. Unlike what many people believed, it was not Taiichi Ohno who invented Just-In-Time but Kiichiro Toyoda. Toyoda said, “People talk about having missed the train just by a minute,” he said, but of course it’s possible to miss a train just by a second. What I mean by ‘Just-in-time’ is not simply that it is important to do something on time, but that is absolutely essential to be precise in terms of quantity and not, for example, produce something on time but in excess, since excess amounts to waste“.

Kiichiro said further “…even a mountain of parts fails to become a vehicle. For the task of coordinating the assembly of thousands of parts, we must design a unique pattern of control and organization. Unless we establish a unique pattern of control and organization, no amount of financial resources will be sufficient.”

The Post-War Toyota

Toyota’s beginning was laden with difficult trials, hardest of which was the impact of the World War II on Japan. Before and during the War, Toyota Motor Company temporarily benefited from military contracts for trucks, but Japan’s surrender in 1945 brought uncertainty and extreme financial hardship. In the eyes of the Allied Occupation, Japan’s large financial groups (zaibatsu) were abettors of the militarists who had led the country to invade Asia, and go to war with Britain and the United States. Kiichiro Toyoda did not know if the Occupation authorities would liquidate his company as step in creating the “new Japan.” Fortunately, the Allies saw Toyota as an asset in the country’s economic revitalization. The Toyota Group was neither dissolved nor significantly altered by the Occupation Reforms. However, this reprieve did not spare Toyota from the extreme shortages and inflation of the postwar years. Also, government protection (tariff reduction and other barriers) was lifted which made it even more difficult for Toyota to compete with American and European cars. In the absence of credit sources and severe economic depression, Toyota was compelled to reduce both production and overhead. Kiichiro began with standard corporate belt-tightening techniques—voluntary management pay cuts and an across-the-board pay cut of 10% for all workers. Yet Toyota fell further into debt, until the company found itself on the verge of bankruptcy. At one point, the company’s debt was more than eight times greater than its total capital value.

When these measures proved inadequate, Kiichiro asked for the voluntary resignation of 1,600 workers. The workers reacted by engaging in strikes, protests, and work stoppages. Kiichiro defused the crisis with an unusual gesture: he publicly took responsibility for the state of the company, and resigned as CEO. The challenges facing Toyota at that time were of course beyond his control. However, his act of self-sacrifice perhaps made the workers reflect on the difficult circumstances facing the company. Work resumed in Toyota’s plants without interruptions, and the company weathered the lean postwar years.

Taiichi Ohno

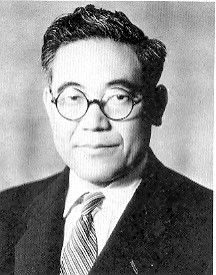

During this time, Toyota lagged in productivity and quality than its American counterpart. It was under these conditions that Taiichi Ohno was brought into the company and one of his initial assignments was to increase the productivity of the Japanese company, which was behind that of Ford by a factor of ten. Taiichi Ohno was assigned as assembly manager and developed many improvements that eventually became the Toyota Production System (TPS). The development of TPS was the reaction to Toyota’s new vision to improve Toyota’s image to customers and the world and to catch up with America in productivity. Admittedly, it appeared that this vision was a collective aspiration at Toyota during that time. But it was Ohno who was most zealous in pursuing the vision. Given the shortage of funds, his approach was continuous elimination of wastes (muda) in the manufacturing process and relying people’s talents/efforts instead of spending money. Thus, he would be very careful in buying new machines or any kind of automation. In fact, Toyota would make over 90% of their own machines exactly to the function needed at the time, not investing in adding features that they might need in the future.

In analyzing Toyota’s situation, Ohno recognized that Japanese workers could not realistically be working ten times less effectively than their American counterparts. Waste and inefficiency must be prevalent and if this could be eliminated from the system, productivity could increase by a factor of ten–or even more! The elimination of waste marked the start of the Toyota Production System and remains the basis from which it has evolved to this day.

Ohno’s early experiments in waste elimination were based within the manufacturing machine shops of which he was in charge. The “one man one machine” approach was seen as the only cost-effective system that a heavily unionized American industry could adopt. The production of large quantities of parts on high-speed, expensive machines creates the potential for an abundance of waste. Ohno experimented with different machine layouts, encouraging workers to become multi-skilled and stopping machines when a job was finished. He encountered many problems during these early stages and learned the need for patience to allow workers to adapt to change.

In 1950 Toyota’s new executives Eiji Toyoda and Shoichi Saito visited US and toured Ford Motor Company’s factories and observed the latest automobile production technology. One especially useful idea they brought home from their visit to Ford resulted in Toyota’s suggestion system, Toyota Creative Ideas and Suggestions System (TCISS), in which every employee was encouraged to make suggestions for improvement of any kind.

In 1954, Toyota through the leadership of Taiichi Ohno, introduced the kanban system. Accordingly, the idea was emulated by Ohno from American supermarket system, where “consumers” (those in the downstream production stage) took “products” (parts) from the stock shelves, and the “storekeepers” (those in the upstream production stage) replenished the stock to the degree that it was depleted.

Toyota Motor Corporation’s vehicle production system is a way of “making things” that is sometimes referred to as a “lean manufacturing system” or a “Just-in-Time (JIT) system,” and has come to be well known and studied worldwide. This production control system has been established based on many years of continuous improvements, with the objective of “making the vehicles ordered by customers in the quickest and most efficient way, in order to deliver the vehicles as quickly as possible.”

The Toyota Production System (TPS) was established based on two concepts: The first is called “jidoka” (which can be loosely translated as “automation with a human touch”) which means that when a problem occurs, the equipment stops immediately, preventing defective products from being produced. The second is the concept of “Just-in-Time,” in which each process produces only what is needed by the next process in a continuous flow. (Later Takt time or demand frequency and Pull System was added to enhance the production system.) Based on the basic philosophies of jidoka and Just-in-Time, the TPS can efficiently and quickly produce vehicles of sound quality, one at a time, that fully satisfy customer requirements. Taiichi Ohno was an excellent originator of new ideas with his own unique management style. His ability to identify the best of a competitor’s systems and to adapt them to the unique situation of the Japanese business environment gave Toyota an unrivalled advantage.

The Kaizen Culture of Toyota

The visions that Toyota pursued were: first efficient cars; second globally respectable cars; third price competitive cars… These visions of did not come all at once, instead, they came one after another according to the issues of its time. But Toyota’s success lies on its people who were its main assets in overcoming crisis and adapting to new market conditions. Decades of difficult trials that the company had been through had been responsible for the development of kaizen culture in Toyota.

It is the leaders that establish the culture of organizations. As for Toyota, leaders starting from Sakichi Toyoda to Kiichiro Toyoda to Taiichi Ohno to Shoichiro Toyoda to Eiji Toyoda, and the later leaders all contributed to shape the culture of the Toyota people. It is a culture that seemed to have been designed all for the purpose of making cars required by the market at the lowest cost possible. The culture at Toyota maybe exemplified by the following tenets called the Toyota Way.

The Toyota Way

- Base your management decisions on a long-term philosophy, even at the expense of short-term goals

- Create continuous process flow to bring problems to the surface

- Use “pull” systems to avoid overproduction

- Level out the workload

- Build a culture of stopping to fix problems, to get quality right the first time

- Standardized tasks are the foundation for continuous improvement and employee empowerment

- Use visual control so no problems are hidden

- Use only reliable, thoroughly tested technology that serves your people and processes

- Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others

- Develop exceptional people and teams who follow your company’s philosophy

- Respect your extended network of partners and suppliers by challenging them and helping them improve

- Go and see for yourself to thoroughly understand the situation (genchi genbutsu)

- Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly

- Become a learning organization through relentless reflection and continuous improvement

The Global Toyota

We know what happened later. Toyota was able to overcome all its crisis and in the 1960s, it set the vision of becoming as a major global player in automobile business. As dearly as 1957, the company entered the American market and in 1958 established a plant in Brazil. In 1961 TQC or Total Quality Control was introduced in Toyota and 1965, Toyota was awarded the Deming Prize. Around this time it was 47th largest non-American corporation and 10th largest auto manufacturers in the world.

In 1969, when Eiji Toyoda was president, Toyota set the vision of “Mass Volume Production for competitiveness”. This vision was made possible through strengthening its dealer network and supplier relationship.

Despite the drastic fall in the demand for automobile during the 1973 international oil crisis, Eiji Toyoda pushed though with the planned expansion of the company following the earlier vision that the automobile would remain to be a “necessity for people at all levels”. During this time, Toyota shifted to general purpose facilities or the synchronized, mixed-stream production (instead of the dedicated model lines) that could be operated according to changes in market demand for the company’s various models. While its Western counterparts were worrying about depressed market demand and downsized their companies, Toyota did not lay off workers, instead prepared the organization to be even more ready for more challenges. Eiji’s vision saw that after the smoke is over, strong demand will return.

In 1974, the company faced a new challenge in the US and in Japan, meet the newly legislated emission standards. Toyota was more than prepared for the challenge as it had been the company philosophy to make efficient engines and vehicles. So the company brought up even more fuel efficient cars with cleaner emission that came with catalytic converters to further cut exhaust pollutants.

In 1983, Toyota entered into a joint venture with General Motors called NUMMI, the New United Motor Manufacturing, Inc, operating an automobile manufacturing plant in Fremont, California. The factory was an old General Motors plant that had been closed for several years. Toyota then started to establish new brands at the end of the 1980s, with the launch of their luxury division Lexus in 1989.

In mid 1990s, Toyota responded to the challenge of the modern times characterized by globalization, environmental and safety issues and diversification of customers’ tastes. Among other things, it courageously pioneered and developed hybrid cars and in 1997, under the when Hiroshi Okuda was president, Toyota introduced Prius as the world’s first mass produced hybrid car. During which time, the company was pursuing the vision: Environmental car without sacrificing driving comfort.

The Toyota’s vision starting 2005 is “Harmonious growth with the environment, global and local community, and stakeholders while establishing long term business infrastructure”. In the same year Toyota produced close to 7 million vehicles and overtook Ford Motor Company in the number 2 spot as the largest automaker in the world according to the data of OICA (International Organization of Motor Vehicles Manufactrurers). This year, many expect that Toyota will be able to overtake General Motors and become the biggest motor vehicle manufacturer the world over. At the pace the company has been growing in the last nine decades Toyota’s plural leadership headed by Chairman Fujio Cho and President Katsuaki Watanabe is as optimistic as ever.

Conclusion:

Visionary Leader Plus Kaizen Organization Equals a Winner

The ideal combination is visionary leadership and a company with a Kaizen culture. Visionary leadership and Kaizen culture will be a formidable partnership. In this kind of combination, a vision is implemented by an organization that continuously refines and improves the vision. It is going to provide a fighting chance for the vision to succeed. A good example of a company that is visionary led and possesses a Kaizen culture is Toyota Motor Company.

Toyota is an example of a company that is visionary led and has an organization possessing a culture of improvement. The kind of visionary leadership in Toyota is unique in that there is no single leader to which its visions can be attributed to. The kind of visionary leadership that Toyota has, maybe termed as “plural visionary leadership” as the vision is owned by the whole management. If ever, the first true visionary of Toyota could be Kiichiro Toyoda, founder of Toyota Motor Company, who saw a great company making fuel efficient automobiles. His vision considered that Japan had no petroleum and lacked natural resources. His solution was Just-In-Time Production System.

The second and probably the most well-known visionary leader in Toyota is Taiichi Ohno. Ohno was not the leader but a manager of Toyota yet he had a clear idea of how the shared leadership vision of “gaining customer acceptance of the Toyota car and increase productivity” were all about. He waged war on waste, improved on the JIT that Kiichiro Toyoda started and developed it further to become what is known as Toyota Production System. There was also Eiji Toyoda, who in 1973 oil crisis, steadfastly pursued the vision of “Mass Volume Production for Competitiveness” – that the car will remain to be a necessity for people at all levels and therefore expansion and improvement plans were not abandoned contrary to what the rest of the world were doing. This perseverance allowed Toyota to improve people capability and became even stronger force to contend in the automobile manufacturing.

Visions and leadership commitment shaped the culture of Toyota. Given the already favorable Japanese culture of hard work, loyalty and respect of leaders; Toyota was enhanced by the studious, inventive and patient model of Sakichi Toyoda (Kiichiro’s father and founder of the Toyota Group). Add to this the single-minded persistency of Ohno in eliminating mura, muri and muda through people’s talents and efforts; Toyota was the ideal breeding ground for development of the culture of called kaizen.

Having a kaizen culture and a leadership driven by visions make Toyota a formidable global player in car manufacturing. There is no other industry so vulnerable and so uncertain in the midst of the current world issues – depletion of petroleum resources, global warming, and financial crisis – than the automotive industry. Yet in the face of all these difficulties, Toyota was able to show phenomenal growth and profitability when its bigger competitors are experiencing retardation and losses.